Can you reduce your inventory by 20% by next quarter?

Supply chain managers often get some goal or target to reduce their inventory by x amount of dollars or a certain percentage. Sometimes this is because the industry benchmark is lower than your own, or because your manager will get a nice bonus out of it.

That being said, it’s always good to assess if you can lower your inventory, as it can tie up a lot of your capital. I’ve seen companies with close to 40% of their annual turnover in inventory. It was well over 100 million USD.

But how do you know how much you can do?

Step 1: Don’t buy what you don’t need

The easiest way to keep your inventory down is to not buy it in the first place.

Critically assess which items you need to stock. E.g. you expect your local supermarket to have shelves full of everyday products like cereal, fruit, vegetables etcetera. But you’re probably okay with having to pre-order that expensive dry-aged wagyu beef you only order once a year. This strategy is often called MTO or made-to-order.

Similarly, it makes little sense stocking up on Christmas trees in March, but all the more sense to do so in November. Only stock items when there’s demand.

Work on your MOQ (Minimum Order Quantities). Often manufacturers will work with enormous MOQs at a cheap price. If you’re thinking of selling 10 smartphones per year, but when you have to order a minimum of 500, that means a 50-year stock. You’ll probably be throwing out 470 at the rate these things become obsolete. So try to negotiate an MOQ that makes sense to your business, even if it means not getting the lower price per unit.

Or can you convince your suppliers to try VMI (Vendor Managed Inventory)? You’ll let your supplier make sure there is enough stock to support your business and you’re only buying the products when you’re at the same time selling them. Walmart e.g. is a big fan of this.

Step 2: Check your inventory’s health

Inventory is often expressed as one lump figure, e.g. it’s 20% of the annual turnover or X amount of dollars. You’ll have to analyze deeper than that.

Dead stock

Dead stock is inventory that just isn’t moving. E.g. Products for which the last x years there hasn’t been a sale. Here you have to check why: is the product inferior to its competitors, just too expensive or simply obsolete?

I once witnessed a conversation between a VP and a supply chain analyst where the VP was demanding that the inventory of a certain car part needed to be reduced, by any creative action he could think of. The analyst said it was impossible. The angry VP asked why he wasn’t willing to cooperate. The analyst said because it’s a car part of a Renault already 25 years out of the market.

Dead stock is the hardest to work on, because often the market just isn’t there anymore.

Slow movers

Slow movers are products that have very few orders, e.g. one per 6 months. At least here you know there is a market. You can try actions like special discounts for your customers, extra marketing actions etcetera.

High runners

High runners are products with a fast inventory turnover. Here it’s easier to lower the inventory because the products are actually moving out at a decent pace. However, watch out to not lower your inventory too much so it creates stock disruptions and you’re losing business.

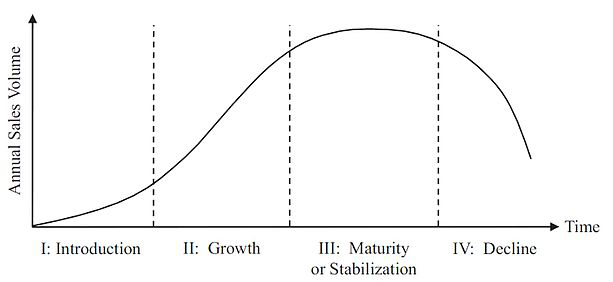

E.g. try to manage your product’s lifecycle so you’ll catch when your higher runner is declining and you’re not stocking inventory for sales that are no longer coming in.

Conclusion

Reducing inventory levels is not an easy task, but often necessary. Inventory ties op working capital that can be used elsewhere and can consume expensive warehouse space. Just keeping it on hand can bleed you dry.

The easiest step is not taking in the stock in the first place. The hardest step is getting rid of stock that’s just not moving. You might have to think a bit creative here.